Most defects in the circuit-board assembly are due to the solder paste or the process of printing solder paste. Since the transition to lead-free soldering, a whole new spectrum of problems has emerged in older paste printing and its due processes. Incomplete coalescence of ball grid array (BGA) spheres and solder paste deposits are failure modes that have increased in frequency since the transition to lead-free soldering. The Xceed enables true 3D measurement and provides the most accurate and repeatable inspection results with the minimum false calls. It’s designed with Advanced Signal Processing which gives results in noise-less, clear, and accurate 3D images.

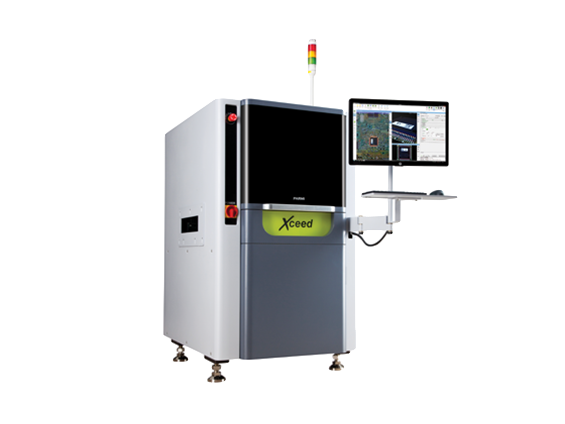

Xceed AOI

- Inspection Irrelevant to Color, Material, Surface Roughness

- Inspection of up to 65mm Height

- Fastest Inspection Speed in the Industry